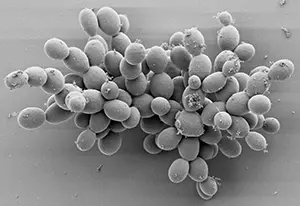

Lallemand is driving innovation in yeast, bacteria and enzyme production, including circular economy practices, renewable energy, and cutting-edge R&D to support feed mills in achieving greater efficiency and sustainability.

The UK feed sector is operating in a tighter environment than it was even a few years ago. Margins remain under pressure, customer specifications are becoming more demanding, and there is growing scrutiny on energy use, emissions and supply chain assurance.

At the same time, mills are expected to deliver consistent nutritional performance and physical quality, often while managing greater variability in raw materials.

Within that context, fermentation-derived ingredients, such as yeasts, bacteria and enzymes, continue to attract attention for the contribution they can make to efficiency and consistency in feed manufacturing and animal performance.

But the conversation is no longer only about product functionality. Increasingly, it is about how those ingredients are produced, how sustainability is measured and reported, and what level of assurance sits behind the manufacturing process.

Lallemand’s recent investments and developments provide a practical case study of how one fermentation specialist is responding to these expectations and where advances are being made.

Embracing the circular economy in yeast production

Lallemand’s yeast production processes exemplify its commitment to the principles of the circular economy, ensuring that byproducts and co-products are managed as sustainably as possible and also transformed into valuable resources.

An element of this approach is the use of molasses – a co-product from sugar production – as a nutrient source in the company’s yeast fermentation processes.

In addition, the company produces vinasses – a nutrient-rich byproduct of yeast fermentation – in seven of its yeast plants across Europe and the United States. These vinasses are repurposed as liquid biofertilisers or livestock feed used by nearby farmers.

Used as a biofertilizer, vinasses can help reduce the greenhouse gas footprint in agricultural fields by decreasing reliance on conventional chemical fertilisers.

By turning industrial byproducts and co-products into agricultural resources, Lallemand helps enhance the environmental footprint of its operations while providing valuable products to farmers.

Energy management and resource efficiency

Lallemand is also helping promote resource efficiency through its approach to wastewater recycling.

In six of its yeast plants, located in the USA, South Africa, Finland, Estonia, and Germany, Lallemand uses biodigesters that convert wastewater yeast effluents, which are full of organic material, into biogas.

Additionally this biogas can be used to power boilers, generating steam that is fed back into the production process. This practice helps reduce the company’s reliance on fossil fuels and helps lower overall greenhouse gas emissions, while simultaneously improving energy efficiency across its production sites.

This wastewater-to-energy approach is one example of where the company turns waste into a resource, helping to close the loop between industrial processes and more sustainable energy production.

Sustainability assessment tools

In line with its commitment to sustainability, the corporate R&D team has developed a new sustainability assessment tool based on its Double Materiality Assessment (DMA) framework.

This tool evaluates the sustainability impact of projects across five key categories: climate change, circular economy, health and safety, supply chain, and product responsibility.

By using this tool to assess R&D projects, Lallemand makes its best efforts to align its innovations with both internal and external sustainability priorities.

The company’s R&D efforts include the development of specific yeast strains for biofuels, enzymatic mycotoxin mitigation, and oral biologics. These are all solutions that not only benefit feed production and human health, but also contribute to broader environmental and societal goals.

Meeting global ESG standards

Lallemand’s commitment to environmental, social, and governance (ESG) principles is reinforced by its adherence to internationally recognised standards.

Nineteen Lallemand sites have achieved ESG certifications and labels since 2023, including ISO 14001 for environmental management, ISO 50001 for energy management, ISO 45001 for occupational health and safety, EcoVadis medals and SMETA audits.

These certifications and labels demonstrate the company’s ongoing commitment to maintaining high operational standards and managing environmental risks effectively, ethical practices and responsible supply chain management. This approach is part of Lallemand’s commitment to continuously improving dedication to quality assurance and operational excellence.

Strategic growth through enzyme innovation

Lallemand’s focus on innovation extends beyond yeast production to encompass its enzyme portfolio, which plays a crucial role in improving feed efficiency and animal health through its usage in silage and environmental inoculants.

In June 2025, Lallemand expanded its enzyme portfolio through the acquisition of Solyve, a leader in the solid-state fermentation of non-GMO enzymes.

Based in Normandy, France, Solyve brings over 35 years of expertise in enzyme production, particularly in the food and beverage sectors, and has been the manufacturer behind the specialist enzyme components of Lallemand’s silage inoculants for over 10 years.

The acquisition strengthens Lallemand’s position in the enzyme market and aligns with its long-term strategy of advancing microbial fermentation technologies.

Solyve’s modern facility will play a central role in Lallemand’s enzyme innovation strategy, enhancing its ability to deliver tailored, sustainable enzyme solutions to the food, beverage, and feed industries.

With this acquisition, Lallemand is well-positioned to continue being a key player in the field of enzyme technologies and support its customers in their environmental transition with high-performance products.

Lallemand’s vision for the future

The company’s approach to sustainability, combined with its commitment to innovation and quality, ensures that the company remains at the forefront of the feed industry.

By embedding sustainability into its operations, from yeast, bacteria and enzyme production to improved energy efficiency, Lallemand is creating value for its customers and partners, and helping to pave the way towards minimising its impact.

The company’s ongoing investment in cutting-edge technologies and its strategic focus on resource efficiency set it apart as a forward-thinking leader in microbial fermentation.

By maintaining a strong focus on quality, sustainability, and technological advancement, Lallemand continues to deliver industry-leading yeast, bacteria and enzyme products that meet the ever-growing demands of feed mills, farmers and agricultural professionals in the UK and beyond.

By Hannah Elliott