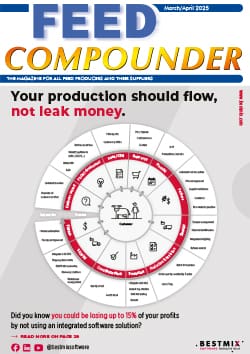

In an industry shaped by tight margins, volatile supply chains, and rising sustainability demands, feed professionals need more than promises — they need reliable software solutions they can trust. For us AI isn’t a future concept. We’re committed to the journey of integrating it into our solutions to support customers in optimising formulation, enhancing production, and boosting efficiency.

While others are still discussing the possibilities and benefits that AI can bring in theory, we already have proven practical experience with AI, delivering measurable results where it matters most. And let’s be clear: AI isn’t here to replace nutritionists. It is designed to enhance their expertise, speed up decision-making, and empower feed producers to reach new levels of precision, performance, and profitability.

AI in Feed Formulation: Beyond Guesswork

Precision is essential in animal nutrition. At BESTMIX, we are developing AI-enabled feed formulation technology designed to help nutritionists quickly generate intelligent, data-driven starting recipes by considering nutrient requirements, ingredient availability, cost and regulatory constraints.

Our AI models analyze extensive historical recipe data—along with external datasets when available—to identify valuable patterns and ingredient combinations that may not be immediately obvious. This helps suggest optimal starting compositions that balance nutritional goals with practical considerations.

Importantly, these models provide transparent, explainable recommendations that clarify the rationale behind ingredient choices, enabling confident and traceable decision-making. This approach is especially valuable for less experienced formulators, allowing them to leverage the company’s accumulated know-how embedded in historical data.

While still under development, this AI-driven approach promises to enhance formulation efficiency, improve animal health and welfare, and deliver faster, more reliable decisions—ultimately supporting sustainable and consistent nutrition strategies.

AI in Production: Reducing Hidden Waste

Many nutritionists and plant managers still rely on experience, spreadsheets, outdated software, and disconnected tools to manage production. As a result, the amount of waste generated during production, downtime, or rework often goes unnoticed.

AI changes this by predicting the optimal process conditions in real time, such as moisture levels and other key production parameters. For instance, in aquafeed extrusion, AI can support operators in adjusting settings to match each formulation, helping to reduce energy consumption, minimise rework, and prevent costly errors.

A recent five-year study demonstrated that applying AI to enhance production processescan save up to €500,000 annually. This is more than just incremental improvement. It is a significant competitive advantage.

AI in Procurement & Planning: See What Others Miss

From fluctuating ingredient prices to silo inventory imbalances, procurement is also an area ready for transformation. By combining historical data, real-time market trends, ingredient availability, and internal production needs with AI, you can:

- Predict demand with greater accuracy

- Minimize storage and logistics inefficiencies

- Suggest cost-effective alternatives that maintain nutritional value while maximizing profitability

- Precisely forecast raw material needs and optimize silo usage

AI helps nutritionists and procurement teams uncover what traditional methods often miss — hidden costs, inefficiencies, and operational bottlenecks. It turns complex planning tasks from hours into minutes, while reducing the risk of human error and costly rework.

In short, it replaces guesswork with strategy — enabling smarter, faster, and more confident decision-making.

The Power of Human & Machine Learning

AI brings speed, scale and powerful predictive capabilities, but it’s nutritionists who contribute context, experience and practical knowledge. For instance, while AI might suggest insects as a valuable protein source, only a nutritionist can determine their appropriate use by assessing animal needs, regulatory frameworks, and market acceptance.

AI in our software solutions is designed to support nutritionists, not replace them. It enhances formulation and production workflows by providing smart, data-driven recommendations that experts can review, refine and confidently apply. It’s a collaborative approach that combines human insight with machine learning to get better, faster and more reliable results.

How to Get Started with AI — Without the Hype

Adopting AI might sound overwhelming, especially in an industry as specialized as animal nutrition. Here’s a quick guide how to adopt AI with confidence:

- Start with a clear goal— whether it’s reducing waste, cutting costs, or improving formulation accuracy. Make sure your data is clean and reliable, because AI is only as effective as the information it’s built on. Work with the right partner— not just any AI vendor, but one who understands feed production, knows your challenges, and brings real, practical value.

At BESTMIX Software, we combine decades of industry experience with advanced AI technology to deliver solutions that work not just in theory, but in your daily operations.

Ready to Lead with AI?

AI is no longer just a future concept. It is already delivering real improvements in feed efficiency, sustainability, and profitability. With our solutions, nutritionists and decision-makers aren’t just preparing for the future — they’re using its benefits today.

If you’re curious how AI can improve your formulation or production processes, or just want to explore what’s possible, let’s talk. Contact Bestmix here.